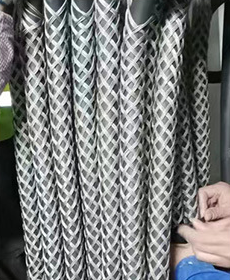

TG Type Cable Dragging Grip | Double-Strand Weaving for Medium Load Traction (800-20,000kg)

Product Parameters

-

Model Series: TG Type (Dragging Cable Grip).

-

Primary Application: Designed for cable head traction and dragging/traction of wires and cables.

-

Load Capacity: Suitable as a middle load network sleeve with breaking loads from 800kg to 20,000kg.

-

Weaving Construction: Utilizes double strand, multi-strand, and other weaving methods for enhanced strength.

-

Design Feature: Double-sided pull type for versatile mid-span or end-pulling operations.

-

Material Options: Available in Hot-Dip Galvanized, Stainless Steel 304, and Stainless Steel 316.

-

Compression Technology: Connection parts include aluminum alloy, stainless steel, and copper sleeve compression.

Found this item cheaper? Contact our customer sales team and we'll look to price match.

Description

Buy the TG Dragging Cable Grip for medium load cable head traction and mid-span dragging. Features double and multi-strand weaving for secure pulling. Max breaking load up to 20,000kg.

Dimensions

Data Overview

| Model | Size Range (mm) | Mesh Length (mm) | Total Length (mm) | Breaking Load (kg) |

| TG-025-24 | 10-13 | 350 | 450 | 800 |

| TG-050-24 | 13-18 | 450 | 550 | 2000 |

| TG-075-24 | 18-25 | 500 | 600 | 2500 |

| TG-100-24 | 25-37 | 600 | 840 | 3500 |

| TG-150-24 | 37-50 | 750 | 1050 | 6000 |

| TG-200-24 | 50-63 | 900 | 1200 | 8000 |

| TG-250-24 | 63-75 | 1050 | 1350 | 8000 |

| TG-300-24 | 75-88 | 1200 | 1500 | 9000 |

| TG-350-24 | 88-101 | 1300 | 1600 | 11000 |

| TG-400-24 | 101-114 | 1400 | 1750 | 12000 |

| TG-450-24 | 115-127 | 1400 | 1750 | 13500 |

| TG-500-24 | 124-152 | 1400 | 1750 | 15000 |

| TG-550-24 | 153-180 | 1400 | 1750 | 20000 |

| TG-600-24 | 180-230 | 1400 | 1750 | 20000 |

| TG-650-24 | 230-280 | 1450 | 1850 | 20000 |

| TG-700-24 | 280-320 | 1600 | 2000 | 20000 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Operational Versatility | Double-sided pull design with dual loops. | Allows for both cable head traction and mid-span dragging operations. | Maximized Flexibility: Adaptable to various cable installation scenarios, reducing the need for multiple specialized tools. |

| Structural Strength | Adopts double strand and multi-strand weaving methods. | Provides a robust mesh structure capable of handling medium to high pulling loads. | Assured Performance: Delivers reliable pulling power for demanding cable installation projects. |

| Material Durability | Choice of HDG, SS 304, or SS 316 wire rope. | Offers excellent resistance to wear and corrosion in diverse environments. | Extended Lifespan: Ensures long-term reliability, minimizing replacement costs and downtime. |

| Secure Connection | Compression parts use aluminum, copper, or stainless steel sleeves. | Ensures a secure and stable connection between the mesh and pulling eyes. | Safety & Compliance: Prevents grip failure under load, protecting personnel and valuable cable assets. |

FAQs

Q1: What is the primary use for the TG Type cable grip?

The TG Type is mainly used for cable head traction and as a middle load network sleeve for dragging and traction of wires and cables.

Q2: What weaving methods are used in the TG series?

The TG series utilizes double strand, multi strand, and other weaving methods to achieve the required strength and flexibility for medium load applications.

Q3: Is the TG grip suitable for mid-span pulling?

Yes, the TG grip features a double-sided pull type design, making it suitable for both end-pulling and mid-span dragging operations.

Q4: What are the available material options for the TG grip?

The cable grip materials can be divided into hot-dip galvanized, stainless steel 304, and stainless steel 316.