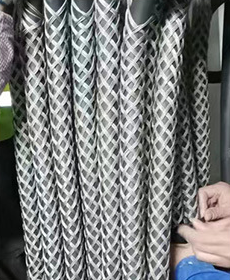

MGS Single Stranded Double-Sided Cable Grip | Light-to-Medium Duty Mid-Span Mesh

Product Parameters

-

Model Series: MGS Type (Single Stranded Double-Sided Pull).

-

Feature (F): Uses single strand weaving for easier threading and connection.

-

Application: Suitable for pulling and dragging cables in the middle (mid-span).

-

Material Options (F): Hot-Dip Galvanized, Stainless Steel 304, or 316.

-

Advantage (A): High elasticity and moderate softness allow the cable to easily pass bends without damage.

-

Benefit (B): Compression parts made via TALURIT/WIROP presses ensure high load reliability.

-

Load Capacity: Breaking load up to 6000kg for MGS-100/110 models.

Found this item cheaper? Contact our customer sales team and we'll look to price match.

Description

The MGS Double-Sided Cable Grip adopts single strand weaving for easy threading and connection. Suitable for pulling and dragging cables in the middle section. Available in SS304, SS316, and Galvanized Steel.

Dimensions

Data Overview

| Model | Size Range (mm) | Mesh Length (mm) | Total Length (mm) | Breaking Load (kg) |

| MGS-4 | 4-6 | 140 | 190 | 100 |

| MGS-8 | 6-9 | 230 | 260 | 100 |

| MGS-12 | 9-12 | 300 | 360 | 200 |

| MGS-16 | 13-18 | 500 | 600 | 425 |

| MGS-22 | 18-25 | 520 | 620 | 625 |

| MGS-30 | 25-37 | 550 | 720 | 875 |

| MGS-45 | 37-50 | 620 | 800 | 3000 |

| MGS-60 | 50-63 | 750 | 980 | 4408 |

| MGS-75 | 63-75 | 900 | 1180 | 4408 |

| MGS-90 | 75-88 | 950 | 1220 | 5000 |

| MGS-100 | 88-101 | 1000 | 1320 | 6000 |

| MGS-110 | 101-114 | 1180 | 1450 | 6000 |

| MGS-125 | 115-127 | 1250 | 1620 | 6500 |

| MGS-135 | 127-152 | 1460 | 1880 | 9000 |

| MGS-160 | 152-180 | 1780 | 2200 | 9000 |

| MGS-200 | 180-230 | 1950 | 2300 | 10000 |

| MGS-250 | 230-280 | 2000 | 2350 | 10000 |

| MGS-280 | 280-320 | 2100 | 2450 | 10000 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Operational Access | Double-sided pull design; cable head can be threaded out. | Enables quick connection and release at any point in the cable run, supporting mid-span installation. | Maximized Efficiency: Significantly reduces labor time and resource consumption. |

| Structural Integrity | Compression connections are formed using Swedish TALURIT and Taiwanese WIROP hydraulic presses. | Delivers a smooth finish and verified high tensile load capacity. | Safety & Compliance: Ensures the connection exceeds safety margins and will not fail under rated load, protecting both infrastructure and personnel. |

| Material Durability | Choice of HDG, SS 304, or SS 316 wire rope. | Allows selection of optimal wear and corrosion resistance for specific environments (e.g., marine or high-humidity). | Extended Lifespan: Ensures long-term reliability and reduced procurement frequency. |

| Cable Protection | Highly flexible, closely woven mesh that tightens under tension but releases when pushed in the opposite direction. | Allows the cable to easily pass bends without injury. | Cost Mitigation: Prevents jacket damage and cable insulation compromise, avoiding expensive cable replacement and project delays. |

FAQs

Q1: What is the key functional difference from standard single-eye grips?

The MGS features a double-sided pull design, with the core value being its support for mid-span cable installation, connection, or detachment. Standard single-eye grips are limited to end-to-end pulling.

Q2: How is the breaking strength of the connection guaranteed?

The connection points are manufactured using professional TALURIT and WIROP hydraulic equipment. This ensures high tensile strength and structural consistency, validated through rigorous pulling tests.

Q3: How do I safely release the grip from the cable without causing damage?

The mesh grip tightens when pulled. To safely release, simply push the mesh against the direction of the pull force (i.e., push the mesh toward the pull eyes).

Q4: Which compression sleeve options are available?

The compression connection parts can be selected from aluminum alloy sleeve compression, copper sleeve compression, or stainless steel sleeve compression.