DSGY Safety Cable Grip | High-Pressure Hose Whip Restraint (Galvanized Steel)

Product Parameters

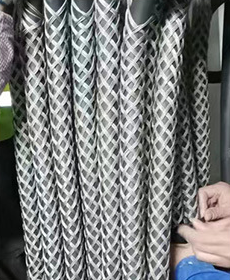

- Product Series: DSGY Type Safety Cable Grip (Safety Rope).

- Material Construction: Manufactured from high-strength galvanized steel wire rope.

- Core Function: Engineered to prevent high-pressure hoses and oil tube sockets from breaking off and causing injury.

- Safety Features: Equipped with integrated springs/buffers along the rope body to absorb shock during sudden pressure releases.

- Application Scope: Essential safety equipment for onshore oilfields, offshore platforms, and industrial high-pressure fluid systems.

- Technical Versatility: Available in rope diameters from 3mm to 12mm with customizable safety factors (N=2:1 to N=4:1).

Found this item cheaper? Contact our customer sales team and we'll look to price match.

Description

Professional DSGY Type Safety Cable Grip designed to prevent high-pressure hose and oil tube sockets from accidental breakaway. Featuring galvanized steel construction with integrated buffer springs for maximum tension and corrosion resistance.

Dimensions

Data Overview

| Rope Dia. (D) (mm) | Loop Length (B) (mm) | Available Total Lengths (L) (cm) | Application Focus |

| 3 – 4 | 40-55 | 30, 40, 50, 60, 70, 80, 100 | Light-duty hose restraint |

| 5 – 6 | 60-70 | 60, 80, 100, 120, 150 | Medium-pressure oilfield lines |

| 8 – 10 | 95-120 | 80, 100, 120, 150 | Heavy-duty industrial sockets |

| 12 | 130-140 | 100, 120, 150 | Maximum pressure safety lines |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Accident Prevention | Specifically designed to link high-pressure hose sockets. | Acts as a redundant “whip restraint” if the primary connection fails. | Personnel Safety: Eliminates the risk of “hose whip,” protecting workers from lethal impact in high-pressure environments. |

| Shock Absorption | Integrated buffer springs distributed along the length (L). | Dampens the kinetic energy of a breakaway event, reducing the instantaneous load on anchor points. | Equipment Protection: Minimizes secondary damage to nearby machinery and structural components during a failure. |

| Environmental Resilience | High-quality galvanized coating for corrosion resistance. | Resists oxidation and salt spray degradation in harsh marine or oilfield conditions. | Long Service Life: Ensures the safety device remains reliable over years of outdoor exposure, reducing replacement costs. |

| Precision Engineering | Customizable lengths (30cm–150cm) and diameters. | Can be tailored to the exact specifications of different hose diameters and pressure ratings. | Operational Flexibility: Provides a perfect fit for a wide range of industrial rigging and oilfield applications. |

FAQs

Q1: What is the primary safety purpose of the DSGY Type cable?

It is primarily used to prevent high-pressure hoses and oil tube sockets from accidentally breaking off, which can cause severe injury or equipment damage.

Q2: Can the safety factor be customized for specific project requirements?

Yes. The safety factor (N) can be produced according to requirements, such as N=2:1, N=3:1, N=3.5:1, or N=4:1.

Q3: Is this product suitable for offshore marine environments?

Absolutely. The use of galvanized steel wire rope provides excellent corrosion resistance, making it ideal for offshore platforms and coastal oilfields.

Q4: How do the integrated springs help in a failure event?

The springs act as buffers to absorb the sudden tension or “snap” when a hose disconnects, preventing the cable from breaking and controlling the movement of the failed hose.