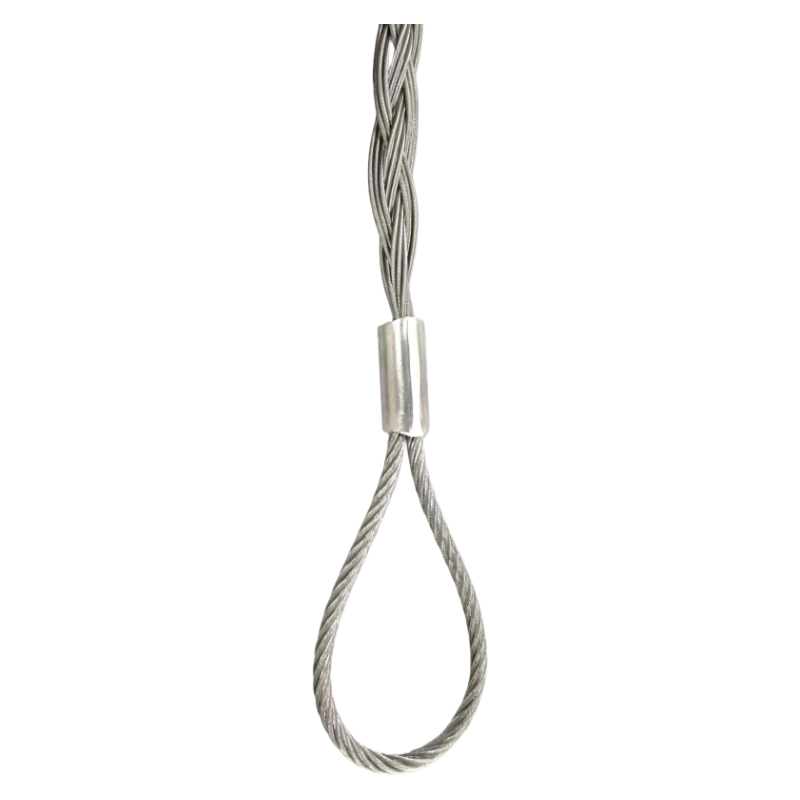

Double-Sided Dragging Cable Grip (MGT Type) – Heavy-Duty Stainless Steel Mesh

Product Parameters

-

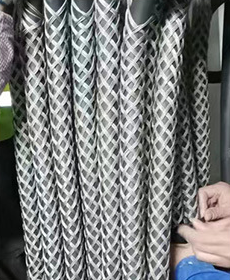

High-Strength Multi-Strand Mesh for Mid-Span Cable Operations

-

Model Series: MGT Type

-

Application: Mid-span cable pulling, dragging, and support.

-

Material Options: Hot-Dip Galvanized, Stainless Steel 304, or Stainless Steel 316/316L.

-

Mesh Structure: Multi-strand composite weaving (Single, Double, or Triple strand).

-

Breaking Load: 580kg to 20,000kg (Dependant on size).

-

Certification: Compression connections manufactured via Swedish TALURIT technology.

-

Key Benefit: "Push-to-release" design allows easy installation without cutting the cable.

Availability: In Stock / Custom Manufacturing Available Min Order: 1 Unit

-

Found this item cheaper? Contact our customer sales team and we'll look to price match.

Description

MGT Multi Strand Double-Sided Cable Grip for pulling/dragging heavy cables in the middle. Features multi-layer composite weaving and reliable TALURIT compression. Max load up to 20,000kg.

Dimensions

Technical Specifications & Size Chart

| Model | Size Range | Mesh length | Total length | Breaking load |

| MGT-12 | 9-12 | 300 | 360 | 580 |

| MGT-16 | 13-18 | 450 | 560 | 1000 |

| MGT-22 | 18-25 | 520 | 620 | 2500 |

| MGT-30 | 25-37 | 550 | 720 | 3500 |

| MGT-45 | 37-50 | 620 | 800 | 6000 |

| MGT-60 | 50-63 | 750 | 980 | 8000 |

| MGT-75 | 63-75 | 900 | 1180 | 8000 |

| MGT-90 | 75-88 | 950 | 1220 | 9000 |

| MGT-100 | 88-101 | 1000 | 1320 | 11000 |

| MGT-110 | 101-114 | 1180 | 1450 | 12000 |

| MGT-125 | 115-127 | 1250 | 1620 | 13500 |

| MGT-135 | 127-152 | 1460 | 1880 | 18000 |

| MGT-160 | 152-180 | 1780 | 2200 | 18000 |

| MGT-200 | 180-230 | 1950 | 2300 | 20000 |

| MGT-250 | 230-280 | 2000 | 2350 | 20000 |

| MGT-280 | 280-320 | 2100 | 2450 | 20000 |

Product Detail

| Key Area | Feature | Advantage | Benefit |

| Operational Access | Adopts multi strand weaving and double-sided pull design; cable head can be threaded out. | Supports the pulling and dragging of heavy cables from the middle (mid-span). | Maximized Efficiency: Enables immediate access and manipulation for heavy-duty installation tasks, reducing downtime. |

| Structural Integrity | Compression connections are formed using Swedish TALURIT and Taiwanese WIROP hydraulic presses. | Ensures a smooth appearance and verified high tensile load. | Safety & Compliance: Guarantees connection stability under heavy load, protecting both the cable and site personnel. |

| Material Durability | Choice of HDG, SS 304, or SS 316 wire rope. | Provides high elasticity, wear resistance, and corrosion resistance. | Extended Lifespan: Ensures tool reliability in harsh environments, justifying investment in heavy-duty equipment. |

| Cable Protection | The cable mesh grip is a mesh structure; it is tight when pulled, but easily released when pushed in the opposite direction. | The grip is durable and, due to its flexibility and moderate softness, will not hurt the cable. | Cost Mitigation: Prevents jacket damage and insulation compromise on expensive heavy cables. |

FAQS

Q1: What differentiates the MGT from the MGS (Single Strand) series?

The MGT uses multi strand weaving and is specifically designed for pulling and dragging heavy cables. The MGS series typically handles lighter loads and uses a simpler single strand weave.

Q2:How is the breaking strength of the connection guaranteed?

The connection points are manufactured using professional TALURIT and WIROP hydraulic equipment. This ensures high tensile strength and structural consistency, validated through rigorous pulling tests.

Q3: How do I safely release the grip from the cable without causing damage?

The mesh grip is designed to tighten the more you pull. To safely release, simply stay in the opposite direction to promote network (i.e., gently push the mesh toward the pull eyes).

Q4: Which materials are available for compression sleeves?

The compression connection parts can be selected from aluminum alloy sleeve compression, copper sleeve compression, or stainless steel sleeve compression.