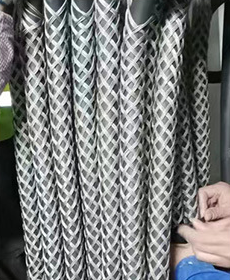

Swaged Soft Loop Slings (EN13411) | Heavy Duty Press Fitted Wire Rope Rigging (WLL 0.3-125T)

Product Parameters

-

-

Product Series: Swaged Soft Loop Slings (Press-Fitted Soft Eye).

-

Standards Compliance: Manufactured referencing EN13411-2-2001, GB/T16762-2009, and GB/T14737-2009.

-

Rope Construction: High-strength 6x37+FC (6-60mm) and 6x61+FC (64-120mm) steel wire rope.

-

Working Load Limit (WLL): Massive capacity range from 0.3 Tonnes to 124.9 Tonnes.

-

Diameter Range: Available in rope diameters from 6mm to 120mm.

-

Safety Assurance: Customizable Safety Factor (n). Standard is 5 to 1 (n=5).

-

Customization: Total Length (L) and Loop Dimensions (A) are fully customizable to client requirements.

-

Found this item cheaper? Contact our customer sales team and we'll look to price match.

Description

Manufacturer of EN13411 Swaged Soft Loop Slings. Features press-fitted sleeves, customizable safety factor (5:1), and WLL up to 124.9 Tonnes. Ideal for heavy construction and industrial lifting.

Dimensions

Data Overview

| Rope Dia (mm) | Soft Loop Dim (mm) | MBL (Tonnes) | WLL (Tonnes) |

| 6 | 120 | 1.6 | 0.3 |

| 8 | 160 | 2.9 | 0.6 |

| 10 | 200 | 4.5 | 0.9 |

| 12 | 240 | 6.5 | 1.3 |

| 16 | 320 | 11.6 | 2.3 |

| 20 | 400 | 18.1 | 3.6 |

| 24 | 480 | 26.1 | 5.2 |

| 32 | 640 | 46.3 | 9.3 |

| 40 | 800 | 72.3 | 14.5 |

| 50 | 1000 | 112.9 | 22.6 |

| 60 | 1200 | 162.4 | 32.5 |

| 72 | 1440 | 224.8 | 45.0 |

| 80 | 1600 | 277.2 | 55.4 |

| 92 | 1840 | 367.1 | 73.4 |

| 100 | 2000 | 434.1 | 86.8 |

| 120 | 2400 | 624.6 | 124.9 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Load Capacity & Performance | Engineered with MBL up to 624.6 Tonnes and WLL up to 124.9 Tonnes. | Capable of handling ultra-heavy loads, from small machinery to massive infrastructure components. | Project Capability: Enables procurement teams to source a single product line for diverse lifting needs, ensuring the site can handle the heaviest lifts required. |

| Manufacturing Standards | Strictly follows EN13411-2-2001 and GB/T16762/14737 standards. | Ensures the rigging meets international safety and quality benchmarks required by global engineering firms. | Risk Mitigation: Guarantees compliance with safety inspections and reduces liability risks associated with lifting failures. |

| Custom Configuration | Length (L) and Safety Factor (n=5:1) are fully customizable. | Provides a “perfect fit” solution for specific crane hook heights and load geometries without on-site modification. | Operational Efficiency: Reduces installation time and labor costs by delivering ready-to-use rigging tailored to the specific job site. |

| Structural Integrity | Utilizes press-fitted (swaged) aluminum or steel sleeves to form the soft loop. | Creates a permanent, high-strength termination that resists unraveling and wear better than hand-spliced loops. | Extended Lifespan: Offers superior durability in harsh construction environments, lowering long-term equipment replacement costs. |

FAQs

Q1: Can I customize the Safety Factor for specific project requirements?

Yes. While the standard production uses a safety factor of n=5 (5:1), we can customize this value (e.g., n=4 or n=3) based on your specific engineering requirements and local regulations.

Q2: What is the specific construction of the wire rope used?

For diameters between 6mm and 60mm, we typically use 6×37(b)+FC wire rope (1670Mpa grade). For larger diameters (64mm to 120mm), we use 6×61(b)+FC wire rope to ensure flexibility and strength.

Q3: How do I specify the length when ordering?

Since “Value L” (Total Length) needs to be fabricated to user requirements, please specify the effective working length (bearing point to bearing point) when requesting a quote. If dimensions for the loop “A” are not specified, standard table values will be applied.

Q4: Do these slings meet European standards?

Yes, our Swaged Soft Loop Slings are manufactured with reference to the EN13411-2-2001 standard, making them suitable for international markets requiring European compliance.