CL60-2H Two-Hole Copper Lug (1/0 AWG / 60mm²) | Long Barrel Dual Stud Terminal

PRODUCT PARAMETERS

-

Model Series: CL-2H (Two-Hole Standard)

-

Design: Dual-Stud Tongue to prevent rotation and maximize mechanical security.

-

Conductor Fit: Optimized for 1/0 A.W.G. / 60 mm² cabling.

-

Material: 99.9% High-Conductivity Seamless Copper Tube.

-

Finish: Electro-Tin Plated for superior corrosion and oxidation resistance.

-

Stud Spacing: Designed for standard NEMA or industrial dual-bolt configurations.

-

Application: Ideal for Switchgear, Transformers, Grounding Busbars, and Data Centers.

Description

Industrial-grade CL-2H two-hole copper lugs for 1/0 AWG (60mm²) conductors. Features a double-stud tongue to prevent terminal rotation and ensure maximum surface contact in high-vibration power systems.

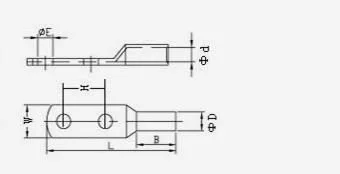

Dimensions

Data Overview

| Item No. | Wire Range (mm²/AWG) | ΦE (mm) Stud Hole | ΦD (mm) Ext. Dia | φd (mm) Int. Dia | W (mm) Width | L (mm) Length | B (mm) Barrel |

| CL60-2H-8 | 60mm² (1/0) | 8.5 | 14 | 11 | 20.5 | 130 | 40 |

| CL60-2H-10 | 60mm² (1/0) | 10.5 | 14 | 11 | 20.5 | 130 | 40 |

| CL60-2H-12 | 60mm² (1/0) | 13 | 14 | 11 | 20.5 | 130 | 40 |

| CL60-2H-14 | 60mm² (1/0) | 15 | 14 | 11 | 20.5 | 130 | 40 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Anti-Rotation Security | Two-hole (Dual Stud) tongue design. | Provides two points of contact, preventing the lug from twisting or loosening under mechanical stress. | System Uptime: Eliminates the risk of “hot spots” caused by loose connections in high-vibration industrial environments. |

| Maximized Conductivity | Pure seamless copper tube body with tin plating. | Provides the lowest possible resistance and prevents galvanic corrosion between dissimilar metals. | Energy Efficiency: Reduces voltage drop across heavy-duty power distribution networks, lowering operational heat. |

| Heavy-Duty Construction | Extended Long Barrel design (130mm total length). | Allows for multiple crimps, providing superior wire pull-out resistance and a gas-tight seal. | Critical Safety: Guarantees a permanent connection that exceeds industrial pull-test requirements for mission-critical power. |

| Standardized Fit | Available in M8 to M14 stud hole configurations. | Matches industrial busbar bolt patterns perfectly without the need for field modification. | Versatility: Simplifies inventory by providing a reliable solution for various dual-bolt equipment interfaces. |

FAQs

Q1: Why use a two-hole lug instead of a standard one-hole lug?

Two-hole lugs are required in high-amperage applications to prevent the terminal from rotating when bolts are torqued. This ensures the contact surface remains flat against the busbar, maintaining electrical integrity and preventing arcing.

Q2:What is the spacing between the two stud holes?

The CL-2H series is designed to meet standard industrial spacing requirements. Please refer to the technical drawing for specific center-to-center dimensions for the CL60-2H series.

Q3: Can these be used for grounding applications?

Absolutely. The high-conductivity seamless copper and tin plating make the CL-2H series an industry standard for grounding busbars in telecommunications and data centers.