8 AWG Copper Compression Lug | 2-Hole 1/4″ Stud, 5/8″ Spacing | 90°C Rated for DLO/Flex Wire

PRODUCT PARAMETERS

-

Product Type: Two-Hole Compression Lug

-

Material: High-Conductivity Copper

-

Coating: Corrosion-Resistant Tin-Plated Finish

-

Wire Compatibility: 8 AWG (Standard & All Flexible Classes: G, H, I, K, M, DLO)

-

Stud Specification: Dual 1/4 Inch (6.4 mm) Holes, 5/8 Inch (16 mm) Spacing

-

Key Features: Inspection Window, Beveled Barrel Entry

-

Certifications: UL Listed (486A-486B), CSA Certified (C22.2 No. 65-13), ABS Approved

-

Performance: 90°C Temperature Rating, 35 kV Maximum Voltage

Description

Secure and reliable dual-hole 8 AWG copper compression lug, tin-plated for corrosion resistance. UL/CSA certified, 90°C, 35kV rated. Accepts Class G, H, I, K, M, and DLO flexible cables.

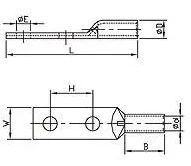

Dimensions

Data Overview

| Specification | Metric Value | Imperial Value |

| Product Type | Compression Lug | Compression Lug |

| Base Material | Copper | Copper |

| Coating | Tin-Plated | Tin-Plated |

| Number of Stud Holes | 2 | 2 |

| Stud Hole Size | 6.4 mm | 1/4 in |

| Stud Hole Spacing | 16 mm | 5/8 in |

| Copper Conductor Size | 8 AWG | 8 AWG |

| Flex Conductor Support | Class G, H, I, K, M, DLO (8 AWG) | Class G, H, I, K, M, DLO (8 AWG) |

| Max Voltage Rating | 35 kV | 35 kV |

| Temperature Rating | 90 °C | 90 °C |

| Overall Length | 46.5 mm | 1.83 in |

| Barrel Length | 10.7 mm | 0.42 in |

| Tongue Width | 12.2 mm | 0.48 in |

| Tongue Thickness | 1.8 mm | 0.07 in |

| Wire Strip Length | 12.7 mm | 1/2 in |

| Installation Die (Panduit) | P21 | P21 |

| Installation Die (Burndy) | 49T | 49T |

| Installation Die (T&B) | 21 | 21 |

Product Detail

| Key Area | Feature | Advantage | Benefit |

| Safety & Compliance | UL Listed (486A-486B), CSA Certified, and ABS Approved. | Meets stringent North American and international safety/quality standards. | Assured Reliability: Guarantees regulatory compliance for high-risk and commercial projects (e.g., marine, industrial). |

| Installation & Quality | Features a clear inspection window and beveled barrel entry. | Allows visual verification of full wire insertion and ensures fast, mistake-free cable seating. | Maximized Efficiency: Speeds up installation time and drastically reduces the risk of faulty crimps and connection failures. |

| Material & Durability | Constructed from high-conductivity copper with a corrosion-resistant tin-plated finish. | Provides superior electrical performance while protecting against oxidation and harsh environments. | Long-Term Performance: Extends the lug’s service life, minimizing maintenance and replacement costs in demanding conditions. |

| Versatility | Rated for 8 AWG conductors, including all flexible classes (G, H, I, K, M, DLO). | Eliminates the need for multiple inventories by accommodating a comprehensive range of flexible cable types. | Operational Flexibility: Simplifies procurement and ensures the right connector is always available for diverse heavy-duty applications. |

Q1: What are the key certifications for this compression lug?

This lug is UL Listed to 486A-486B (File #E52164), CSA certified C22.2 No. 65-13, and ABS approved. These certifications ensure the product meets high standards for safety, reliability, and performance in various industrial and marine applications.

Q2: Can this lug be used with highly flexible cables like DLO or Class K/M?

Yes. This lug is engineered to accommodate the full range of flexible copper cables, including Class G, H, I, K, M, and DLO, all at the specified 8 AWG size.

Q3: What is the benefit of the tin-plated finish?

The tin-plated finish provides excellent resistance against oxidation and corrosion. This is crucial for maintaining low-resistance electrical connections over the long term, especially in humid or corrosive industrial environments.

Q4: How do I ensure proper installation?

Always strip the wire to the specified length of 1/2 inch (12.7 mm). The lug features an inspection window to visually confirm the conductor is fully inserted before crimping. Use the specified tooling: Panduit Die P21, Burndy Die 49T, or T&B Die 21.