6 AWG Copper Compression Lug | 2-Hole 3/8″ Stud, Universal 3/4-1″ Spacing | Blue Code

PRODUCT PARAMETERS

-

Product Type: Two-Hole Compression Lug (Universal Spacing)

-

Material/Finish: High-Conductivity Seamless Copper, Electro-Tinned Plated

-

Conductor Size: 6 AWG (Stranded)

-

Stud Specification: Dual 3/8 Inch Holes

-

Mounting Feature: Universal Slotted Hole Spacing (Adjustable 3/4" to 1")

-

Key Features: Inspection Window, 90°C Rated, Seamless Barrel

-

Wire Strip Length: 1-1/8 Inches

-

Certifications: UL Listed (up to 35 kV), CSA Certified

-

Color Code: Blue

Description

Versatile 6 AWG stranded copper compression lug with universal 3/4″ to 1″ slotted hole spacing. Features dual 3/8″ stud holes and inspection window. UL/CSA certified for 35 kV and 90°C applications.

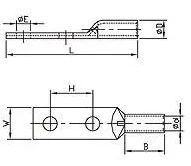

Dimensions

Data Overview

| Specification | Imperial Value | Metric Equivalent |

| Product Type | Compression Lug (Slotted) | Compression Lug (Slotted) |

| Base Material | Copper | Copper |

| Coating | Electro-Tinned Plated | Electro-Tinned Plated |

| Conductor Size | 6 AWG (Stranded) | 6 AWG (Stranded) |

| Number of Stud Holes | 2 | 2 |

| Stud Hole Size | 3/8 in | 9.5 mm |

| Hole Spacing (Adjustable) | 3/4 in – 1 in | 19.1 mm – 25.4 mm |

| Barrel Type | Standard (Implied by strip length) | Standard |

| Inspection Window | Yes | Yes |

| Wire Strip Length | 1-1/8 in | 28.6 mm |

| Max Voltage Rating | 35 kV | 35 kV |

| Temperature Rating | 90 °C | 90 °C |

| Color Code | Blue | Blue |

| Certifications | UL, CSA | UL, CSA |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Mounting Flexibility | Features a slotted tongue design accommodating 3/4″ to 1″ universal spacing. | Allows the lug to fit perfectly onto bus bars and terminals with non-standard or varying stud center distances. | Reduced Inventory & Rework: Eliminates the need to stock multiple fixed-spacing lugs, streamlining installation and reducing potential site mismatches. |

| Electrical Performance | Manufactured from seamless, high-conductivity copper and electro-tinned plated. | Minimizes resistance and prevents oxidation, ensuring the lug maintains maximum current flow efficiency. | Long-Term Reliability: Guarantees a stable, cool-running connection over the product’s lifespan, even under high load (up to 35 kV). |

| Installation Accuracy | Includes an inspection window and a precise 1-1/8 inch strip length. | Provides visual confirmation of full wire insertion and simplifies the wire preparation process. | Guaranteed Crimp Quality: Assures that the conductor is correctly seated for a certified, permanent termination, reducing installation risk. |

| Compatibility & Standards | UL Listed (35kV) and CSA Certified, specifically for 6 AWG stranded cable. | Meets the strictest electrical safety and quality standards across North America. | Safety & Compliance: Ensures the component is approved for use in critical infrastructure and commercial projects. |

FAQs

Q1: What is the main advantage of the universal hole spacing on this lug?

The universal spacing, provided by the slotted holes, allows a single lug part number to be used on equipment with stud centers ranging from 3/4 inch to 1 inch (19.1 mm to 25.4 mm). This flexibility solves common fit-up issues in the field.

Q2: What size hardware is required for this lug?

The lug features 3/8 inch (9.5 mm) holes, requiring 3/8-inch bolts and nuts for mounting. The slotted design ensures the bolts can be securely positioned anywhere within the 3/4″ to 1″ spacing range.

Q3: How do I ensure proper crimping for the 6 AWG wire?

First, strip the wire precisely to 1-1/8 inch (28.6 mm). Second, confirm the wire is visible through the inspection window. Finally, use the correct die set corresponding to the Blue color code to ensure a certified, permanent connection.

Q4: Is this lug compatible with flexible copper cables?

This lug is specifically rated for stranded copper conductor sizes. While often compatible with Class B/C stranded cables, for highly flexible classes (G, H, K, M, DLO), the manufacturer’s specific approval for those classes should be confirmed against the UL listing details.