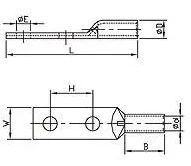

2 AWG Long Barrel Copper Compression Lug | 2-Hole 1/4″ Stud, 5/8″ Spacing | Flex Cable Ready

PRODUCT PARAMETERS

-

Product Type: Two-Hole Compression Lug

-

Material/Finish: High-Conductivity Copper, Tin-Plated

-

Conductor Size: 2 AWG (Supports all flexible classes: G, H, I, K, M, DLO)

-

Barrel Type: Long Barrel (1.36 in / 34.5 mm)

-

Stud Specification: Dual 1/4 Inch (6.4 mm) Holes, 5/8 Inch (16 mm) Spacing

-

Key Features: Inspection Window, Beveled Entry, Straight Tongue

-

Certifications: UL Listed, CSA Certified, ABS Approved

-

Performance: 90°C Temperature Rating, 35 kV Maximum Voltage

Description

High-performance 2 AWG copper compression lug featuring a 1.36-inch long barrel for maximum conductivity and crimp strength. Dual 1/4″ studs with 5/8″ spacing and inspection window. UL/CSA/ABS certified for all flexible copper cables.

Dimensions

Data Overview

| Specification | Metric Value | Imperial Value |

| Product Type | Compression Lug | Compression Lug |

| Base Material | Copper | Copper |

| Coating | Tin-Plated | Tin-Plated |

| Conductor Size | 2 AWG | 2 AWG |

| Flex Conductor Support | Class G, H, I, K, M, DLO | Class G, H, I, K, M, DLO |

| Number of Stud Holes | 2 | 2 |

| Stud Hole Size | 6.4 mm | 1/4 in |

| Stud Hole Spacing | 16 mm | 5/8 in |

| Barrel Type | Long | Long |

| Overall Length | 73.4 mm | 2.89 in |

| Barrel Length | 34.5 mm | 1.36 in |

| Tongue Width | 17.8 mm | 0.7 in |

| Tongue Thickness | 2.8 mm | 0.11 in |

| Wire Strip Length | 36.5 mm | 1-7/16 in |

| Max Voltage Rating | 35 kV | 35 kV |

| Temperature Rating | 90 °C | 90 °C |

| Color Code | Brown | Brown |

| Installation Die (Panduit) | P33 | P33 |

| Installation Die (Burndy) | 10 | 10 |

| Installation Die (T&B) | 33 | 33 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Connection Integrity | Long Barrel Design (1.36 in / 34.5 mm) with 1-7/16 in (36.5 mm) strip length. | Provides a substantially larger area for conductor seating and superior metal-to-metal contact post-crimp. | Maximum Conductivity: Ensures the lowest possible resistance and optimal heat dissipation, extending the life of the connection and cable. |

| Universal Compliance | UL Listed (486A-486B), CSA Certified, and ABS Approved. | Meets key regulatory and safety standards for industrial, commercial, and maritime applications. | Assured Project Acceptance: Guarantees that your installation will be compliant with most North American and international safety codes. |

| Installation Efficiency | Features a clear inspection window and a precise color-coded die index (Brown / P33 / 10). | Allows quick visual confirmation of proper wire placement and ensures correct tool selection during the crimping process. | Reduced Labor Costs: Minimizes installation errors and rework time, providing confidence in every termination. |

| Flexible Cable Support | Rated for 2 AWG including high-flex classes (G, H, I, K, M, DLO). | Perfectly designed to terminate flexible cables often found in heavy mobile equipment and battery systems. | Operational Versatility: Delivers a secure, certified connection for dynamic environments where vibration and tight bends are common. |

FAQs

Q1: What is the benefit of the 5/8 inch stud spacing on this lug?

The 5/8 inch (16 mm) spacing is a very common standard for power distribution blocks and small-to-medium sized equipment terminals, ensuring direct compatibility and easy mounting without requiring additional adapters or custom plates.

Q2: What is the correct preparation for the 2 AWG cable with this long barrel?

The cable must be stripped to 1-7/16 inches (36.5 mm). The lug features an inspection window to visually verify that the 2 AWG conductor is seated completely inside the 1.36-inch long barrel before applying the crimp.

Q3: Is the brown color code important?

Yes. The brown color code corresponds to the specific crimp die index required for this 2 AWG lug (Panduit P33, Burndy 10, T&B 33). Using the correct color-matched die ensures the certified, permanent connection and full safety compliance.

Q4: Can this lug handle high vibration or shock applications?

The long barrel design provides superior mechanical stability and strain relief compared to standard barrels. Combined with the ABS certification (often required for marine/shock environments), this lug is ideal for installations prone to vibration.