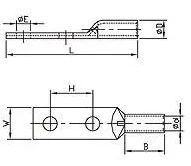

1/0 AWG Copper Compression Lug (Long Barrel) | 2-Hole 3/8″ Stud, 1″ Spacing | Flex Cable Approved

PRODUCT PARAMETERS

-

Product Type: Two-Hole Compression Lug

-

Material/Finish: High-Conductivity Copper, Tin-Plated

-

Conductor Size: 1/0 AWG (Supports all flexible classes: G, H, I, K, M, DLO)

-

Barrel Type: Extra Long Barrel (1.5 in / 38.1 mm)

-

Stud Specification: Dual 3/8 Inch (9.5 mm) Holes, 1 Inch (25.4 mm) Spacing

-

Key Features: Inspection Window, Beveled Entry, Straight Tongue

-

Certifications: UL Listed, CSA Certified, ABS Approved

-

Performance: 90°C Temperature Rating, 35 kV Maximum Voltage

Description

Heavy-duty 1/0 AWG copper compression lug with extra-long 1.5-inch barrel for maximum crimp security. Features dual 3/8″ studs, 1-inch spacing, and an inspection window. UL/CSA/ABS certified for all flexible copper cables.

Dimensions

Data Overview

| Specification | Metric Value | Imperial Value |

| Product Type | Compression Lug | Compression Lug |

| Base Material | Copper | Copper |

| Coating | Tin-Plated | Tin-Plated |

| Conductor Size | 1/0 AWG | 1/0 AWG |

| Flex Conductor Support | Class G, H, I, K, M, DLO | Class G, H, I, K, M, DLO |

| Number of Stud Holes | 2 | 2 |

| Stud Hole Size | 9.5 mm | 3/8 in |

| Stud Hole Spacing | 25.4 mm | 1 in |

| Barrel Type | Long | Long |

| Overall Length | 93.2 mm | 3.67 in |

| Barrel Length | 38.1 mm | 1.5 in |

| Tongue Width | 21.6 mm | 0.85 in |

| Tongue Thickness | 3.3 mm | 0.13 in |

| Wire Strip Length | 39.7 mm | 1-9/16 in |

| Max Voltage Rating | 35 kV | 35 kV |

| Temperature Rating | 90 °C | 90 °C |

| Color Code | Pink | Pink |

| Installation Die (Panduit) | P42 | P42 |

| Installation Die (Burndy) | 12 | 12 |

| Installation Die (T&B) | 42 | 42 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| High Amperage Security | 1/0 AWG conductor size with an Extra-Long Barrel (1.5 in / 38.1 mm). | Provides superior conductivity and maximized contact area for handling high-current applications. | Optimal Power Transfer: Ensures safe, cool, and efficient operation in heavy electrical systems, reducing risk of burnout. |

| Installation Assurance | Clear inspection window and specific 1-9/16 in (39.7 mm) strip length. | Allows installers to visually confirm full, correct conductor insertion before applying the crimp. | Zero Error Guarantee: Eliminates the guesswork in field installation, assuring a perfect, code-compliant termination every time. |

| Broad Application Use | UL/CSA/ABS Certified and supports all copper flexible cable classes (G, H, I, K, M, DLO). | Guarantees acceptance across diverse industries, from industrial to maritime and motor applications. | Procurement Simplicity: One reliable lug that meets multiple regulatory and technical requirements, simplifying inventory management. |

| Durability & Mounting | Tin-plated copper construction with dual 3/8″ stud holes spaced at 1 inch. | Provides robust corrosion resistance and high mechanical strength for secure, high-torque bolting. | Long-Term Reliability: Ensures a vibration-proof and highly durable connection designed for the most demanding environments. |

FAQs

Q1: Why is this lug suitable for high-amperage applications?

This lug is designed for 1/0 AWG conductors, capable of handling significantly higher current loads than smaller AWG sizes. The extra-long 1.5-inch barrel maximizes the electrical and mechanical contact area, ensuring efficient heat dissipation and conductivity under load.

Q2: How do I correctly prepare the wire for this long-barrel lug?

The wire must be stripped to precisely 1-9/16 inches (39.7 mm). The inspection window allows you to verify that the 1/0 AWG conductor has reached the stop inside the barrel, ensuring a full and secure termination before crimping.

Q3: Which dies should be used for crimping this specific lug?

For reliable and certified installation, use the corresponding die indexes: Panduit Die P42, Burndy Die 12, or T&B Die 42. Using the correct pink color code ensures proper compression.

Q4: What are the bolt requirements for mounting this lug?

This lug features two bolt holes with a diameter of 3/8 inch (9.5 mm), spaced 1 inch (25.4 mm) apart. This configuration is a common standard, allowing for robust mounting to bus bars or equipment terminals using 3/8-inch bolts.