Precision Metal Stamping Services

High-Efficiency, Cost-Effective Metal Forming Solutions with Micron-Level Accuracy. From Prototype to Mass Production.

Advanced Tooling & High-Speed Stamping Excellence

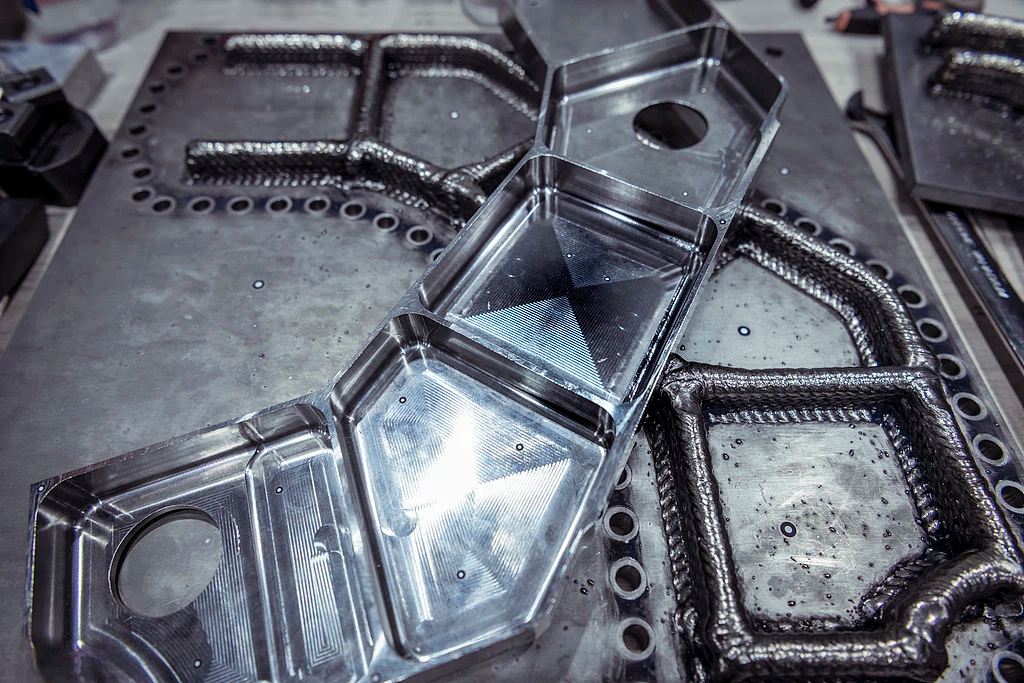

At XLUIG, our metal stamping capabilities combine advanced tooling design with high-speed production. Whether it’s complex deep-drawn components or high-volume progressive die parts, we deliver consistency that exceeds international standards (ISO, DIN, ASTM).

Our Stamping Capabilities

Progressive Die StampingIdeal for high-volume, complex parts. Our in-house tooling team designs dies that can reach up to 1,500 SPM (Strokes Per Minute).

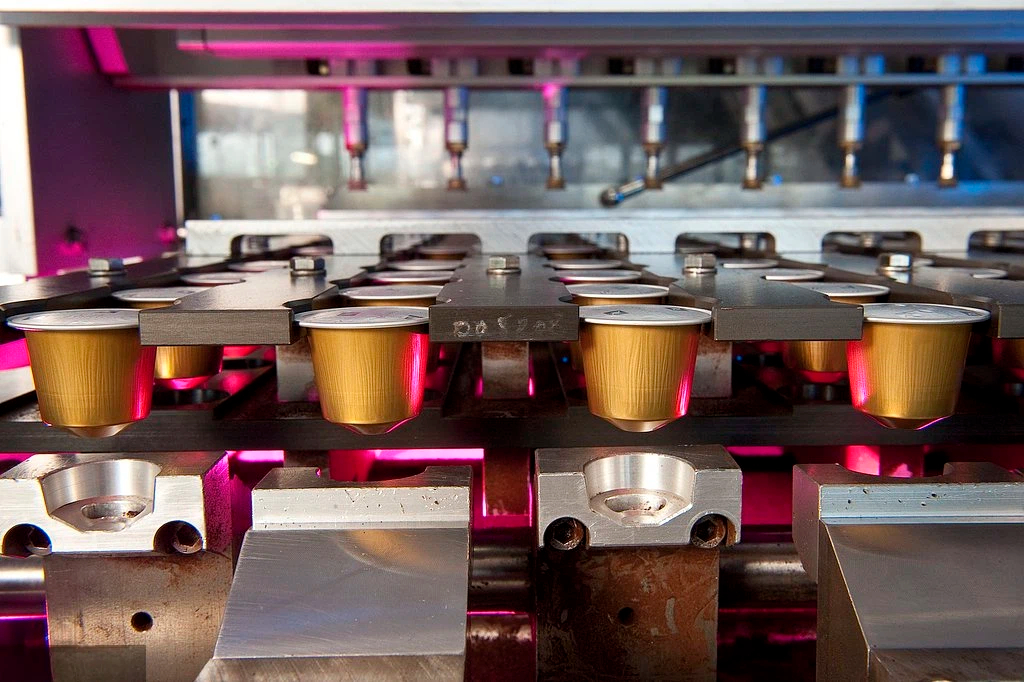

Deep Drawn StampingSpecialized in producing seamless 3D cylindrical or box-shaped components where the depth exceeds the diameter.

Precision Blanking & PiercingDelivering clean-cut edges and tight tolerances (+/- 0.003mm) for critical industrial hardware.

Custom Tooling & PrototypingRapid prototyping (3-10 days) to verify designs before investing in mass-production hard tooling.

Engineering Specifications & Production Limits

| Característica | Capabilities / Range |

| Press Tonnage | 30T – 600T (High-speed & Traditional) |

| Materials | Stainless Steel, Aluminum, Brass, Copper, Carbon Steel, Special Alloys |

| Material Thickness | 0.04mm – 6.0mm |

| Tolerance Range | Up to ±0.003mm (Depending on geometry) |

| Secondary Operations | Heat Treatment, Plating, Aqueous Cleaning, Deburring, Assembly |

| QC Verification | CMM, Spectrometer, Projector, Salt Spray Test |

Industry Applications

Automotive SystemsHigh-strength components for safety and powertrain systems. We meet strict IATF standards for airbag housings and engine brackets.

Electronics & TelecomMicron-precision stamping for connectors and EMI shielding. High-speed production ensures consistent conductivity for 5G devices.

Industrial & FastenersHeavy-duty brackets and structural supports. Verified by Junker Vibration Testing to ensure integrity under extreme mechanical stress.

Medical DevicesBiocompatible components for surgical instruments and micro-implants. We ensure high cleanliness and precision for medical enclosures.

Renewable Energy & EVSpecialized stamping for EV busbars and cooling plates. Our Deep Drawing technology produces seamless battery and inverter housings.