KS Series Non-Insulated Pin Terminal | Copper Needle Crimp Connector | Industrial Electrical Lug

PRODUCT PARAMETERS

-

Model Series: KS Series (Pin/Needle Type)

-

Material: 99.9% Pure Seamless Copper for optimal signal and power transfer.

-

Plating: Electro-Tin Plated to resist oxidation and maintain low contact resistance.

-

Design: Friction-grip needle surface ensures a secure fit within clamping units.

-

Compatibility: Designed for high-density wiring in PLC controllers, breakers, and terminal strips.

-

Safety: One-piece construction prevents splitting during high-pressure crimping.

Description

High-quality KS series non-insulated pin terminals made from premium T2 copper. Designed for secure connections in terminal blocks and tight spaces. Tin-plated for maximum conductivity and corrosion resistance.

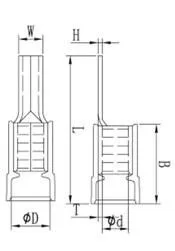

Dimensions

Data Overview

| Item No. | Wire Range (mm2) | Pin Diameter (D) mm | Internal Dia (d) mm | Pin Length (F) mm | Barrel Length (B) mm | Total Length (L) mm |

| KS1.25 | 0.5 – 1.5 mm2 | 1.9 | 1.7 | 10.0 – 12.0 | 4.8 | 15.0 – 17.0 |

| KS2 | 1.5 – 2.5 mm2 | 1.9 | 2.3 | 12.0 | 4.8 | 17.0 |

| KS5.5 | 4 – 6 mm2 | 2.7 | 3.4 | 13.0 | 6.8 | 21.0 |

| KS10 | 10 mm2 | 4.3 | 4.5 | 14.0 | 8.0 | 24.0 |

| KS16-13 | 16 mm2 | 5.5 | 5.8 | 13.0 | 10.0 | 26.0 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Precision Fit | Slim Needle Design | Fits perfectly into narrow European-style terminal blocks where standard lugs cannot enter. | Versatility: Reduces the need for custom terminal blocks, simplifying your inventory. |

| Electrical Integrity | Seamless T2 Copper Body | Eliminates the risk of barrel opening, ensuring uniform pressure during the crimping process. | System Stability: Lowers voltage drops and prevents localized overheating at connection points. |

| Durability | Corrosion-Resistant Tinning | Creates a robust barrier against moisture, acids, and industrial pollutants. | Long Service Life: Ideal for harsh environments, reducing terminal failure and maintenance downtime. |

| Ease of Use | Internal Barrel Chamfer | Allows for fast and clean wire insertion without strand fold-back. | Efficiency: Speeds up mass production and field installations, ensuring 100% wire capture. |

FAQs

Q1: Why choose KS series over insulated needle terminals?

KS series (non-insulated) are preferred for high-temperature environments or when custom heat-shrink tubing is required for specific insulation standards. They also offer a more compact profile for maximum space efficiency in crowded panels.

Q2: Are these terminals compatible with both solid and stranded wires?

Yes. The KS series is specifically optimized for stranded copper wires, as the crimp barrel compresses the strands into a solid mass for maximum contact, but they can also be used with solid wires with the correct crimp die.

Q1: What is the benefit of the “needle” shape?

The needle (pin) shape is designed to convert a standard wire end into a solid plug. This prevents wire strands from fraying and ensures a secure, high-pressure connection in screw-down or spring-clamp terminal blocks.