GHP-90° Series Angled Copper Lug | 90 Degree Right-Angle Battery Terminal | Heavy Duty Tinned Copper

PRODUCT PARAMETERS

-

Model Series: GHP-90° (Right-Angle Series)

-

Design: 90-Degree Vertical Bend for space-saving cable routing.

-

Material: 99.9% High-Conductivity Seamless Copper Tube.

-

Finish: Electro-Tin Plated to prevent oxidation and "green death" corrosion.

-

Structure: Seamless one-piece construction for maximum mechanical strength.

-

Application: Ideal for compact control panels, battery rack stacking, and tight-clearance inverter connections.

Description

Premium GHP-90° series right-angle copper tube terminals. Designed for 90-degree vertical cable routing in tight spaces. Features high-conductivity seamless copper with tin plating for superior corrosion resistance.

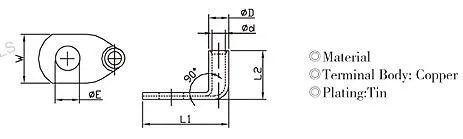

Dimensions

Data Overview

| Item No. | Wire Range (mm2) | Stud Hole (E) mm | Internal Dia (d) mm | External Dia (D) mm | Tongue Width (W) mm | Barrel Depth (B) mm |

| GHP10-90°-6 | 10 mm2 | 6.5 | 4.7 | 6.7 | 12.0 | 11.0 |

| GHP16-90°-8 | 16 mm2 | 8.5 | 5.6 | 7.6 | 12.0 | 13.0 |

| GHP25-90°-8 | 25 mm2 | 8.5 | 7.1 | 9.1 | 13.0 | 14.0 |

| GHP35-90°-10 | 35 mm2 | 10.5 | 8.2 | 10.6 | 15.5 | 17.0 |

| GHP50-90°-10 | 50 mm2 | 10.5 | 9.5 | 12.5 | 18.0 | 19.0 |

| GHP70-90°-12 | 70 mm2 | 13.0 | 11.5 | 15.0 | 21.5 | 22.0 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Space Management | 90-Degree Right-Angle bend design. | Allows cables to be routed vertically or flush against the mounting surface in confined spaces. | Easy Installation: Eliminates the need for large-radius cable loops, saving critical space in compact enclosures and battery cabinets. |

| Reliable Connectivity | Seamless T2 Copper construction. | Ensures uniform current flow and prevents the barrel from splitting during high-pressure crimping. | System Safety: Provides a permanent, low-resistance connection that handles high-amperage surges without overheating. |

| Environmental Protection | Premium Electro-Tin Plating. | Provides a sacrificial barrier against moisture, salt spray, and chemical exposure. | Long-Term Performance: Maintains clean contact surfaces for years, reducing maintenance costs in marine or industrial environments. |

| Engineered Precision | Beveled Internal Chamfer entry. | Guiding the wire strands into the barrel smoothly without fraying or snagging. | Installation Speed: Ensures 100% of wire strands are included in the crimp, guaranteeing electrical integrity and safety. |

FAQs

Q1: When should I use GHP-90° lugs instead of standard straight lugs?

GHP-90° lugs are specifically designed for applications where the cable must enter the terminal block or battery stud vertically. They are essential for preventing excessive stress and bending fatigue on cables in shallow cabinets where a straight lug would not allow the door to close.

Q2: Does the 90-degree bend affect the electrical conductivity?

No. Because the GHP series is manufactured from a single piece of high-purity seamless copper tube, the electrical path remains continuous. The bend is engineered to maintain the same cross-sectional area, ensuring no increase in resistance or heat.

Q3: What is the recommended crimping method for angled lugs?

We recommend using a hydraulic crimping tool with the appropriate hex die size for the cable. Due to the 90-degree angle, ensure the lug is positioned securely in the tool to maintain the correct orientation of the tongue during the crimping process.