2 AWG Single-Hole Copper Compression Lug (Long Barrel) | 5/16″ Stud | NEBS Certified

PRODUCT PARAMETERS

-

Product Type: Single-Hole Compression Lug

-

Material/Finish: High-Conductivity Copper, Tin-Plated

-

Conductor Size: 2 AWG

-

Barrel Type: Long Barrel (1.16 in / 29.5 mm)

-

Stud Specification: Single 5/16 Inch (7.9 mm) Hole

-

Key Features: Beveled Barrel Entry, Straight Tongue

-

Certifications: UL Listed, CSA Certified, ABS Approved, NEBS Level 3 Certified

-

Performance: 90°C Temperature Rating, 35 kV Maximum Voltage

Description

Premium 2 AWG single-hole copper compression lug featuring a long 1.16″ barrel and 5/16″ stud size. Tin-plated, UL/CSA certified, and NEBS Level 3 compliant for high-vibration and critical telecommunications installations.

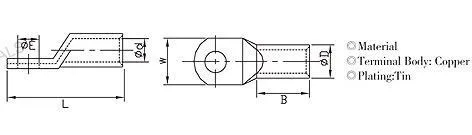

Dimensions

Data Overview

| Specification | Imperial Value | Metric Equivalent |

| Product Type | Compression Lug | Compression Lug |

| Base Material | Copper | Copper |

| Coating | Tin-Plated | Tin-Plated |

| Conductor Size | 2 AWG | 2 AWG |

| Number of Stud Holes | 1 | 1 |

| Stud Hole Size | 5/16 in | 7.9 mm |

| Tongue Angle | Straight | Straight |

| Inspection Window | No | No |

| Barrel Type | Long | Long |

| Overall Length | 2.27 in | 57.7 mm |

| Barrel Length | 1.16 in | 29.5 mm |

| Tongue Width | 0.66 in | 16.8 mm |

| Tongue Thickness | 0.1 in | 2.5 mm |

| Wire Strip Length | 1-1/4 in | 31.8 mm |

| Max Voltage Rating | 35 kV | 35 kV |

| Temperature Rating | 90 °C | 90 °C |

| Color Code | Brown | Brown |

| Installation Die (Panduit) | P33 | P33 |

| Installation Die (Burndy) | 10 | 10 |

| Installation Die (T&B) | 33 | 33 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Connection Security | Long Barrel Design (1.16 in / 29.5 mm) with 1-1/4 in (31.8 mm) strip length. | Provides a large crimp area, maximizing contact and strain relief for the terminated 2 AWG conductor. | Maximized Pull-Out Strength: Ensures a permanent, robust connection that withstands high mechanical stress and vibration. |

| Critical Reliability | UL/CSA Certified and NEBS Level 3 Compliance (No inspection window). | Engineered for the most demanding environments where equipment must resist shock, vibration, and temperature extremes. | Assured Uptime: Guarantees certified performance in mission-critical applications like telecommunications and utility infrastructure. |

| Mounting Versatility | Single 5/16 inch (7.9 mm) stud hole configuration. | Allows for versatile, compact termination on smaller terminal blocks, single-point grounding applications, and equipment with limited mounting space. | Simplified Routing: Ideal for applications requiring quick, flexible cable routing and single-point attachment. |

| Precision Installation | Standardized Brown Color Code (P33 / 10 / 33 die indices). | Ensures the installer uses the correct crimp die required for certified installation of 2 AWG copper lugs. | Code Compliance: Guarantees the necessary compression force is applied for a permanent, low-resistance termination. |

FAQs

Q1: How do I ensure proper wire seating since this model has no inspection window?

Since there is no inspection window, accurate wire preparation is crucial. The 2 AWG wire must be stripped precisely to the specified length of 1-1/4 inches (31.8 mm). The solid barrel design ensures maximum conductor containment and gas-tight integrity once the correct crimp is applied.

Q2: What is the benefit of the 5/16 inch stud hole size?

The 5/16 inch (7.9 mm) stud hole is a heavy-duty size, offering a higher torque capability than a 1/4 inch hole. This is beneficial in industrial applications where secure, high-force bolting is necessary to prevent loosening under vibration.

Q3: Can this single-hole lug be used in environments requiring NEBS certification?

Yes. This lug is explicitly rated for NEBS Level 3 compliance, making it suitable for high-reliability network equipment and telecommunications applications where resistance to vibration, shock, and temperature variations is mandatory.

Q4: Which crimp tool color code corresponds to this 2 AWG single-hole lug?

The required crimp tool die index is identified by the Brown color code, corresponding to Panduit P33, Burndy 10, and T&B 33 indices. Always match the die index to the color code for a certified connection.