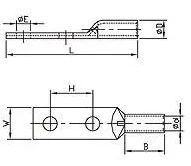

6 AWG Standard Barrel Copper Compression Lug | 2-Hole 1/4″ Stud, 1″ Spacing | NEBS Certified

PRODUCT PARAMETERS

-

Product Type: Two-Hole Compression Lug

-

Material/Finish: High-Conductivity Copper, Tin-Plated

-

Conductor Size: 6 AWG

-

Barrel Type: Standard Barrel (0.81 in / 20.6 mm)

-

Stud Specification: Dual 1/4 Inch (6.4 mm) Holes, 1 Inch (25.4 mm) Spacing

-

Key Features: Inspection Window, Beveled Entry, Straight Tongue

-

Certifications: UL Listed, CSA Certified, NEBS Level 3

-

Performance: 90°C Temperature Rating, 35 kV Maximum Voltage

Description

Certified 6 AWG copper compression lug with standard 0.81-inch barrel and inspection window. Features dual 1/4″ studs with 1-inch spacing. UL/CSA and NEBS Level 3 approved for reliable telecommunications and high-density applications.

Dimensions

Data Overview

| Specification | Metric Value | Imperial Value |

| Product Type | Compression Lug | Compression Lug |

| Base Material | Copper | Copper |

| Coating | Tin-Plated | Tin-Plated |

| Conductor Size | 6 AWG | 6 AWG |

| Number of Stud Holes | 2 | 2 |

| Stud Hole Size | 6.4 mm | 1/4 in |

| Stud Hole Spacing | 25.4 mm | 1 in |

| Barrel Type | Standard | Standard |

| Overall Length | 66.3 mm | 2.61 in |

| Barrel Length | 20.6 mm | 0.81 in |

| Tongue Width | 12.2 mm | 0.48 in |

| Tongue Thickness | 2.1 mm | 0.08 in |

| Wire Strip Length | 22.2 mm | 7/8 in |

| Max Voltage Rating | 35 kV | 35 kV |

| Temperature Rating | 90 °C | 90 °C |

| Color Code | Blue | Blue |

| Installation Die (Panduit) | P24 | P24 |

| Installation Die (Burndy) | 7T | 7T |

| Installation Die (T&B) | 24 | 24 |

Product Features & Engineering Logic

| Key Area | Feature | Advantage | Benefit |

| Critical Reliability | UL/CSA Certified and NEBS Level 3 Compliance. | Meets stringent standards required for equipment reliability in environments subject to vibration, heat, and seismic events (e.g., telecommunications). | Mission-Critical Assurance: Guarantees performance and safety compliance for use in sensitive and essential infrastructure projects. |

| Installation Accuracy | Clear inspection window and designated 7/8 inch (22.2 mm) wire strip length. | Enables quick visual confirmation that the 6 AWG conductor is fully and correctly seated prior to crimping. | Prevents Failure: Eliminates incomplete wire insertion, which is a leading cause of connection failure and overheating. |

| Mounting Standardization | Dual 1/4 inch stud holes with precise 1 inch (25.4 mm) center spacing. | Aligns perfectly with industry-standard bus bar and terminal block configurations. | Seamless Integration: Allows for fast, standardized installation on existing infrastructure, saving time and ensuring a reliable mechanical connection. |

| Durability & Identification | Tin-plated copper body with Blue Color Code (P24 / 7T / 24 die). | Provides superior corrosion resistance and features clear identification for the correct tooling selection. | Consistent Quality: Ensures the lug lasts longer in adverse conditions and guarantees the crimp is executed with the exact, certified force. |

FAQs

Q1: What does the “Standard Barrel” length mean for a 6 AWG lug?

The standard barrel (0.81 inches) design is optimized for environments where space is a constraint, or where the added strength of a long barrel is not strictly necessary. It ensures certified electrical performance while maintaining a compact overall profile.

Q2: How do I ensure this lug is compatible with my equipment?

This lug features a standard 2-hole configuration with a 1-inch (25.4 mm) center-to-center spacing between the 1/4 inch bolt holes. This is a common mounting pattern used in distribution panels and power equipment requiring a 6 AWG connection.

Q3: Is this lug rated for use with flexible cables?

While not explicitly listing all flexible classes, the UL and CSA certifications (486A-486B, C22.2 No. 65-13) typically cover standard stranding. For specific flexible cable classes (G, H, K, M, DLO), consult the manufacturer’s official approval documentation or technical datasheet.

Q4: Which crimp tool and die should I use for the blue color code?

The blue color code indicates that you must use the specified crimp die indices: Panduit P24, Burndy 7T, or T&B 24. Using the correct die is mandatory to achieve the necessary compression for a permanent, reliable, and certified termination.