Gasket Compression Set & Zero-Leakage Testing Standards | XLUIG

You might already know that initial seal tightness doesn’t guarantee long-term performance.

But do you know exactly why gaskets fail after months of service?

It usually comes down to one invisible factor: the material’s “memory.”

At Kunshan Xinluan New Material Technology Co., we know that relying on basic tensile data isn’t enough to predict longevity. You need precise validation.

In this guide, you’re going to learn the critical relationship between Gasket Compression Set & Zero-Leakage Testing.

We’ll break down the physics of stress relaxation, the specific capabilities of XLUIG testing instruments, and how to ensure your seals meet the strictest ASTM and ISO standards.

Let’s dive in.

Understanding Gasket Compression Set

At XLUIG, we know that a seal is only as good as its ability to rebound. When we talk about Gasket Compression Set & Zero-Leakage Testing | XLUIG, we are essentially evaluating the “memory” of the elastomeric material. If a gasket forgets its original shape after being squeezed between two flanges, it loses the internal pressure required to maintain a seal. This loss of resilience is the leading cause of leaks in long-term static applications, making compression set analysis a critical step in material validation.

Defining Material Memory & Deformation

Engineers often face the challenge of viscoelastic material behavior, where rubber exhibits both viscous (fluid-like) and elastic (spring-like) characteristics. When a gasket is under load, we want the elastic properties to dominate. However, factors like heat and chemical exposure accelerate the material’s tendency to flow rather than bounce back. We measure this using the permanent deformation percentage—a metric that tells us exactly how much sealing force has been permanently lost. If the material cannot push back against the mating surface, the integrity of the system is compromised.

Elastic Recovery vs. Plastic Deformation

To ensure reliability, we must distinguish between temporary shape change and permanent failure. Here is how we break down the material response during testing:

- Elastic Recovery: The ability of the polymer chains to return to their equilibrium state once the compressive load is removed. High recovery means a tighter, longer-lasting seal.

- Plastic Deformation: The irreversible change in the material structure. Once a gasket undergoes plastic deformation, it takes the shape of the groove or flange permanently, creating a potential leak path if the joint moves or relaxes.

ASTM D395 & ISO 815 Testing Protocols

We do not guess when it comes to compliance; we test strictly against ASTM D395 Method B and ISO 815 standards. These protocols are the industry benchmarks for determining compression set under constant deflection.

- Method B Focus: We typically compress the specimen to 25% of its original thickness using calibrated spacer bars.

- Duration & Heat: Standard tests run for 22 to 70 hours at elevated temperatures (often up to 100°C+ for silicone) to simulate accelerated aging.

- Calculation: We measure the thickness before and after the recovery period to calculate the percentage of set.

By adhering to these rigorous standards, we provide data that allows you to predict seal life accurately before a single part is installed in the field.

Zero-Leakage Testing Standards

At XLUIG, our commitment to sealing integrity drives our rigorous testing protocols. We move beyond standard leak rates to establish true “zero-leakage” benchmarks, ensuring absolute containment for critical applications in aerospace and industrial enclosures.

ASTM F37 Sealability Metrics

We utilize established metrics, aligning with standards like ASTM F37, to quantify the sealing properties of gasket materials under controlled clamping loads. This precise validation ensures that every seal meets specific liquid or gas permeability testing requirements before it ever reaches a production line.

Identifying Interfacial & Permeation Leakage

Effective validation requires distinguishing between the two primary paths of fluid escape. Our testing isolates these failure modes to determine the root cause of leakage:

- Interfacial Leakage: Occurs when fluid escapes between the gasket surface and the flange face, often due to insufficient surface adaptation or low compression.

- Permeation Leakage: Happens when fluid passes directly through the void structure of the elastomeric material itself.

High-Pressure Failure Detection

To guarantee safety in volatile environments, we perform hydrostatic pressure testing and differential pressure decay analysis. These methods subject seals to accelerated stress conditions, identifying potential blowout points and ensuring the gasket retains its structure under extreme operational pressures.

Compression Set & Leakage Correlation

At XLUIG, we understand that a gasket’s ability to “bounce back” is directly tied to its ability to seal. There is a critical link between compression set values and the risk of system failure. If a material suffers from high permanent deformation, it loses the elastic memory required to fill the microscopic imperfections between mating surfaces, inevitably leading to leaks.

Impact of Sealing Force Retention

The primary driver of a secure seal is sealing force retention. This is the ongoing “push back” force the gasket exerts against the flange or housing.

- Force Decay: As compression set increases, the internal restoring force of the elastomer decreases.

- Gap Formation: Once the sealing force drops below the internal system pressure, fluid or gas bypasses the barrier.

- Testing Focus: We validate that materials maintain sufficient contact pressure throughout their service life to prevent interfacial leakage.

Stress Relaxation & Thermal Cycling Effects

Static testing isn’t enough. Our protocols account for stress relaxation accelerated by environmental factors. Thermal cycling—the repeated heating and cooling of the assembly—drastically impacts viscoelastic material behavior.

- Heat Aging: High temperatures accelerate polymer chain scission, causing the gasket to harden and take a permanent set faster.

- Cold Shrinkage: Low temperatures can cause the material to contract, reducing sealing pressure momentarily.

- System Compensation: In rigid assemblies, engineers often utilize DIN 6796 conical spring washers to maintain bolt tension as the gasket material naturally relaxes over time.

Predicting Long-Term Seal Failure

We don’t just measure current performance; we predict the future. By correlating ASTM D395 data with zero-leakage testing benchmarks, we identify the exact point where a seal will fail.

- Accelerated Simulation: We run tests over 22 to 70 hours (or longer) at elevated temperatures to mimic years of service.

- Failure Thresholds: We establish specific compression set percentages that signal the end of a seal’s useful life.

- Preventative Data: This allows our clients to select materials that ensure zero-leakage assurance rather than managing acceptable leak rates.

XLUIG Precision Testing Capabilities

At XLUIG, we treat validation as the backbone of product reliability. We do not rely on theoretical datasheets; we verify material performance using advanced instrumentation designed for rigorous elastomeric stress relaxation studies. Our facility is engineered to push sealing materials to their limits, ensuring that the compression recovery data we provide represents true field performance.

Integrated High-Temp Compression Jigs

Our testing rigs feature Integrated High-Temp Compression Jigs capable of maintaining precise deflection under extreme thermal cycles. This setup allows us to perform accelerated thermal aging analysis strictly aligned with ASTM D395 Method B and ISO 815 standards. By simulating the harsh environments found in automotive engines and industrial machinery, we ensure that the vulcanization characteristics of the rubber maintain integrity when heat and pressure combine.

Micron-Level Sensor Accuracy

Zero-leakage is not a vague promise; it is a measurable metric. We utilize sensors with Micron-Level Accuracy to detect minute changes in gasket thickness and the resulting permanent deformation percentage. This high-resolution monitoring is critical for static seal verification, ensuring that even under hydrostatic pressure testing, the material maintains the necessary contact stress to prevent interfacial leaks.

Real-Time Force & Recovery Data Analysis

Understanding viscoelastic material behavior requires more than a simple “before and after” measurement. Our systems provide Real-Time Force & Recovery Data Analysis, tracking sealing force retention throughout the entire test duration.

- Continuous Monitoring: We track how the material resists load over time to identify early stress relaxation risks.

- Predictive Modeling: The data helps us optimize polymer cross-linking density for maximum longevity.

- Failure Prevention: We detect potential O-ring failure points before mass production begins.

Real-World Application Scenarios

We see the true value of our Gasket Compression Set & Zero-Leakage Testing when applied to critical industries where material failure is not an option. It is not just about generating lab data; it is about ensuring operational safety and system longevity in harsh environments.

- Automotive Powertrain & Cylinder Heads: Engines subject seals to aggressive thermal cycling and constant vibration. Our testing ensures that cylinder head gaskets maintain high-pressure sealing capabilities without suffering from premature stress relaxation, effectively preventing oil leaks and compression loss.

- Chemical Processing & VOC Prevention: In facilities handling volatile organic compounds (VOCs), sealing integrity is a strict regulatory requirement. We validate that fluid control components resist chemical degradation and maintain a tight seal to prevent hazardous emissions. To ensure the assembly holds tight, it is often critical to pair quality elastomers with a heavy-duty bolting washer to maintain constant flange pressure.

- Aerospace Sealing Integrity: Aircraft seals must endure rapid pressure changes and extreme temperature shifts. We test for permanent deformation limits to guarantee that door seals, window gaskets, and fuel system components retain their elasticity and recovery properties during flight.

Material Selection & Data Interpretation

At XLUIG, we treat material selection as a precise science, not a guessing game. Interpreting the data from our material characterization tests allows us to match the exact physical properties of an elastomer to your specific application requirements, ensuring safety and reliability.

Acceptable Compression Set Percentages

The permanent deformation percentage is the most honest metric for a seal’s lifespan. Simply put, a lower percentage indicates higher resilience and better “memory.” If the number is high, the gasket has failed to recover its thickness, leading to gaps. We analyze results typically within a 25%–50% compression range to verify that the material retains its ability to seal effectively after the load is released.

Comparing EPDM, Silicone, and FKM

We test various elastomeric materials to see how they handle real-world stress.

- Silicone: Tested rigorously in our high-temperature cycles (up to 100°C+) to ensure it doesn’t become brittle or lose elasticity.

- EPDM & FKM: We evaluate these for specific chemical exposures and environmental aging.

Our data helps you decide which material offers the best sealing force retention for your specific operating environment, whether it’s aerospace or industrial enclosures.

Optimizing Polymer Cross-Linking Density

The internal chemistry of the rubber dictates its performance. Polymer cross-linking density directly influences how a material resists elastomeric stress relaxation. By studying the vulcanization characteristics, we can predict whether a seal will maintain its integrity or suffer from premature plastic deformation. We help you optimize these density levels to ensure the gasket provides consistent “push-back” against the mating surfaces for the duration of its service life.

Frequently Asked Questions (FAQs)

What is the difference between compression set and stress relaxation?

While both metrics predict seal failure, they measure different physical behaviors. Compression set focuses on the permanent deformation percentage of the material after the load is removed—essentially, how much the gasket fails to “bounce back” to its original shape. If a seal stays flattened, it loses its ability to fill the gap.

In contrast, elastomeric stress relaxation measures the loss of sealing force retention while the material is still under compression. A gasket might look fine visually but could be pushing back against the flange with significantly less force than when installed, leading to leaks under pressure. We analyze both to ensure your seals maintain integrity under long-term load.

How does thermal aging affect gasket leakage?

Heat is the enemy of elastomeric longevity. Through thermal aging analysis, we observe that prolonged exposure to high temperatures accelerates the cross-linking density in polymers. This causes the material to harden, lose elasticity, and become brittle.

As the gasket loses its viscoelastic properties, it can no longer compensate for flange movement or vibration. This degradation creates micro-pathways for fluid or gas to escape. Our testing simulates these conditions to verify that materials can withstand specific temperature cycles without catastrophic failure.

Why is Method B preferred for O-ring testing?

We rely heavily on ASTM D395 Method B because it tests under constant deflection rather than constant force. In most real-world engineering applications, O-rings and seals are installed into grooves of a fixed depth, compressing them to a specific percentage (usually 25%).

Method B mimics this reality by using precise spacers and non-standard CNC components to maintain a set gap during the test. This provides a far more accurate prediction of how the seal will perform in a static flange assembly compared to Method A, which allows the compression height to vary.

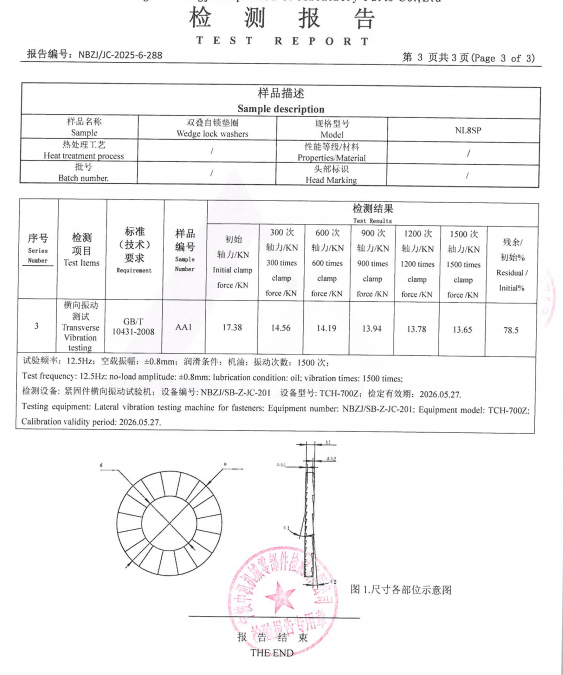

XLUIG Wedge Lock Washer Test Report (NBZJ-288)

XLUIG-Wedge-Lock-Washers-Vibration-Test-Report-NBZJ-288