The Physics of Plating: How XLUIG Validates Connection Reliability through Salt Spray Testing

In industrial applications, the reliability of a terminal depends not only on its metal substrate but also on its surface engineering. At XLUIG, we understand that the plating layer is the final defense for industrial connectors against system failure.

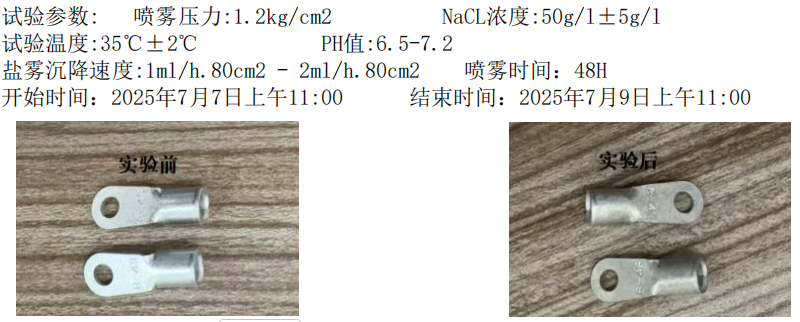

1. 48-Hour Rigorous Validation: The 8-4S Salt Spray Challenge

Our commitment to surface engineering goes beyond theoretical claims. According to the latest quality control data, the XLUIG 8-4S Copper Lug has successfully passed the industry-leading corrosion resistance validation:

- Test Standard: Conducted in accordance with GB/T 10125-2015 (NSS) standards within a salt spray test chamber for 48 consecutive hours.

- Harsh Conditions: The test environment maintained a temperature of 35 deg C +/- 2 deg C, a NaCl concentration of 50g/l +/- 5g/l, a pH value of 6.5-7.2, and a spray pressure of 1.2kg/cm2.

- Test Results: After 48 hours of accelerated aging in high-salinity and high-humidity environments, the sample surface showed no substrate exposure and was officially judged as Qualified.

2. Three Critical Functions of Plating

Behind this successful test result lies XLUIG’s adherence to the three pillars of plating physics:

- Corrosion Resistance (The Shield): While our T2 copper substrate offers excellent conductivity, it is vulnerable to oxidation. By applying a Tin (Sn) plating layer, we create a dense barrier that prevents oxygen and moisture from reaching the copper base.

- Electrical Integrity: Precisely controlled plating thickness minimizes contact resistance. If the plating is porous or inconsistent, oxides build up rapidly, causing resistance spikes and potential overheating hazards.

- Mechanical Durability: Terminals endure significant pressure during the crimping process. Our process ensures the coating is ductile enough to deform with the metal without cracking or flaking, maintaining a gas-tight seal.

3. Why Micron-Level Tolerance Matters

Why do we obsess over micron (um) level precision? Because the plating layer must operate within a strict “Goldilocks” zone:

- Risks of being “Too Thin”: Leads to microscopic porosity, accelerating galvanic corrosion and compromising solderability retention.

- Risks of being “Too Thick”: Can cause material embrittlement, leading to cracking during crimping and creating dimensional tolerance issues that affect fitment.

Conclusion: Transparent Data, Trusted Connections

Every test report, such as LP25-1873, is a testament to our promise. By combining our R&D expertise with rigorous testing at our manufacturing facility, XLUIG ensures that every terminal delivered maintains long-term, stable electrical connections even in the harshest environments.