24H Salt Spray Test vs Real World Years XLUIG Lab Insights

You’ve likely asked the “Golden Question” of manufacturing: If my part survives 24 hours in a salt spray chamber, will it last a full year outdoors?

It is the most debated topic in Quality Control, and the answer often determines whether a supplier gets approved or rejected.

At Kunshan Xinluan New Material Technology Co., we don’t just run the tests; we interpret the critical gap between ASTM B117 standards and actual environmental exposure.

In this analysis, we’re cutting through the industry myths to reveal the true correlation of 24H Salt Spray Test vs. Real-World Years using exclusive XLUIG Lab Insights.

Let’s decode the data.

The ‘Rule of Thumb’: Estimates vs. Reality

One of the most frequent questions we field at XLUIG Laboratory is simple yet complex: “If my product survives 24 hours in the chamber, how long will it last outdoors?” Clients need to translate accelerated corrosion testing data into a tangible service life prediction for their customers.

While there is no perfect mathematical formula that converts lab hours directly to calendar days—primarily because nature is unpredictable—we use established industry benchmarks to guide our analysis. The goal isn’t to predict the exact date of failure, but to establish a reliable baseline for environmental exposure correlation.

The Industry Generalization: 24 Hours NSS ≈ 1 Year?

In the world of ISO 9227 neutral salt spray and ASTM B117 standard testing, we often apply a rough conversion factor to help clients visualize durability. Based on our lab data and general industry acceptance, the correlation generally looks like this:

- 24 Hours Salt Spray: Approximately 1 year of natural environmental exposure (or roughly 120 days in severe coastal conditions).

- 96 Hours Salt Spray: Approximately 4 years of natural exposure.

- 192 Hours Salt Spray: Approximately 8 years of natural exposure.

It is crucial to understand that these figures represent a “constant attack” environment. Our salt fog chamber testing subjects materials to a continuous 5% NaCl solution at 35°C. In the real world, your product faces UV radiation, drying cycles, and varying temperatures. Therefore, we treat these numbers as comparative tools for quality control rather than absolute guarantees of lifespan.

Why the Math Isn’t Linear: Variables That Matter

At XLUIG, we emphasize that service life prediction is never a straight line. While we use rough benchmarks—like equating 24 hours of testing to approximately one year of exposure—real-world corrosion is dictated by chaotic variables that a controlled lab cannot perfectly replicate. A component installed in a dry, rural environment faces a completely different lifespan than the same part used in a coastal industrial zone, even if they both pass the same ASTM B117 standard test.

The calculation fails to be linear because nature introduces factors that basic salt fog chambers exclude:

- UV Radiation: Sunlight degrades coatings, accelerating failure in ways salt mist alone cannot.

- Pollutants: Industrial sulfur dioxide or acid rain creates chemical reactions different from our standard 5% NaCl solution.

- Temperature Fluctuations: Our labs hold a steady 35°C (±1°C), whereas outdoor environments cycle between freezing and scorching, causing thermal expansion and micro-cracking.

The Mechanism of Attack: Continuous Wetness vs. Wet/Dry Cycles

The fundamental difference between our lab data and field results lies in the moisture cycle. The ISO 9227 neutral salt spray test is designed for accelerated corrosion testing by subjecting parts to a state of continuous wetness. In this environment, the test subject is constantly bombarded with atomized salt mist, preventing the material from drying out.

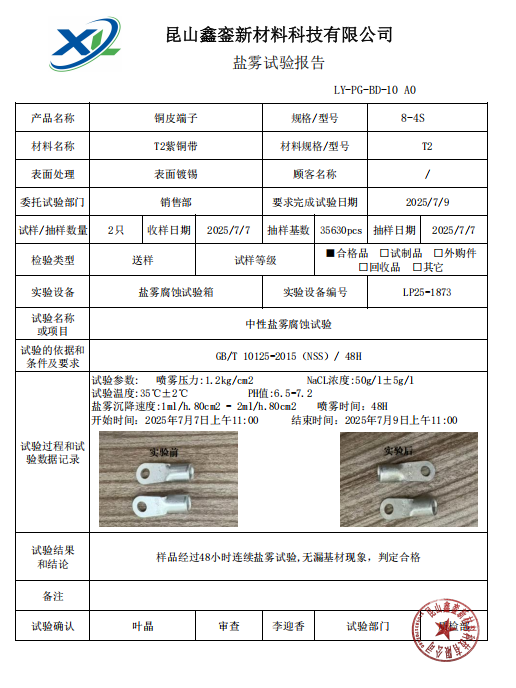

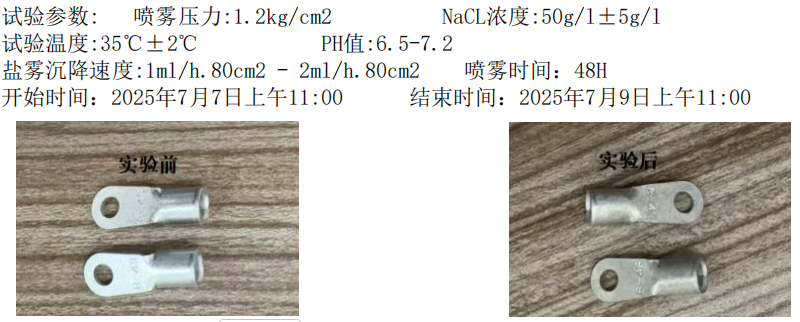

In the real world, atmospheric oxidation simulation is more complex. Nature involves wet/dry cycles. When a material dries, it often forms a passive oxide layer that can temporarily slow down corrosion—a defense mechanism that is stripped away in the relentless environment of a salt spray chamber. This is why we test critical hardware, such as 2 AWG single hole lugs, to withstand the worst-case scenario of constant attack, ensuring they exceed the demands of actual intermittent exposure. By removing the “drying” phase, we force failures to happen in days rather than years, giving us immediate, actionable data on coating discontinuities and material durability.

Material Specifics in Salt Spray Testing

Zinc, Passivates, and Powder Coated Parts Behavior

At XLUIG Lab, we know that not all corrosion looks the same. The way a material reacts inside the salt fog chamber testing environment depends heavily on its surface chemistry. We don’t just watch for “rust”; we monitor specific failure mechanisms that tell us about the quality of the manufacturing process.

For zinc plating durability, the timeline of failure is distinct. Zinc is sacrificial, meaning it corrodes to protect the steel beneath it.

- White Rust: This is the first sign of degradation. It appears as a white, chalky powder (zinc oxide). If this appears too early, the passivation layer was likely weak or applied incorrectly.

- Red Rust: This is the critical failure point. It indicates the zinc layer has been depleted and the base steel is oxidizing. For safety-critical components like EN13411 wire rope rigging, delaying the onset of red rust is the primary goal of our quality control.

Powder coating salt spray resistance operates on a different principle. Since the coating acts as a barrier rather than a sacrificial anode, we look for adhesion failure rather than surface oxidation.

- Scribe Creep: We often scratch (scribe) the panel to see how far rust spreads underneath the paint from a damaged area.

- Blistering: According to ASTM D714, we check for bubbles forming under the coating, which signals poor surface preparation or contamination before painting.

Understanding white rust vs red rust and coating adhesion helps us pinpoint exactly where a production batch might be falling short, ensuring that the surface finishing quality control meets global standards before the product ever leaves the factory.

XLUIG Lab Insights: How We Benchmark Quality

Standardization is Key: Controlling pH and Fallout Rate

At XLUIG, we don’t just throw parts in a box and wait for rust. Real surface finishing quality control requires strict adherence to global protocols like the ASTM B117 standard and ISO 9227 neutral salt spray methods. If the testing environment isn’t calibrated perfectly, the results are just noise. We treat our lab as a precision instrument, not a storage room.

We focus on the invisible variables that make or break a test:

- pH Balance: We keep the solution strictly between 6.5 and 7.2. If it drifts, the corrosion rate skews, making the data useless.

- Fallout Rate: The salt fog must collect at a specific rate (1.0 to 2.0 ml per hour). Too little fog means a slow test; too much drowns the sample.

- Temperature Control: Maintaining a constant 35°C is non-negotiable for consistent chemical reactions.

This precision allows us to accurately validate high-performance treatments, such as our Dacromet coating products, ensuring they meet the exact specifications you need for harsh environments. By controlling these inputs in our salt fog chamber testing, we ensure that a “pass” in our lab translates to genuine reliability in your field.

The True Purpose of Salt Spray Testing

Process Control and Defect Detection over Time Travel

Let’s be real about what happens in the lab. The biggest misconception we encounter is treating the salt spray cabinet like a time machine. It isn’t designed to tell you exactly how many years a product will last in a specific environment. Instead, its true power lies in Process Control and comparative analysis.

At XLUIG, we use Salt fog chamber testing primarily as a quality audit tool rather than a precise predictor of service life. It answers the critical question: “Is the coating on this batch as good as the previous one?” If a standard zinc plating process usually yields 96 hours of resistance but suddenly fails at 48, we immediately know there is a drift in the manufacturing line—perhaps a dirty tank or incorrect chemical balance.

Why we prioritize this test for Quality Assurance:

- Benchmarking Consistency: It provides a standardized baseline to compare different suppliers or production batches globally.

- Early Defect Detection: We identify design flaws, such as coating discontinuities or issues with Galvanic corrosion protection, before mass production begins.

- Risk Mitigation: Catching failures early reduces downstream costs and after-sales maintenance issues.

This method is essential for maintaining strict Surface finishing quality control. By stressing the material in a controlled environment, we expose hidden flaws like porosity or poor adhesion that wouldn’t be visible to the naked eye. This rigor ensures that critical components, such as those requiring zero hydrogen embrittlement protocols, maintain their integrity under stress. We aren’t predicting the future; we are securing the present quality.

Interpreting Your Test Report: White Rust vs. Red Rust

When we analyze results from an ASTM B117 standard test at the XLUIG lab, we don’t just look for “rust.” We distinguish between two critical stages of corrosion that tell the story of your product’s zinc plating durability. Understanding the difference between white and red rust is essential for accurate service life prediction.

- White Rust: This is the first sign of trouble. It appears as a white, chalky powder on the surface. This indicates that the zinc coating (the sacrificial layer) is corroding to protect the steel underneath. While it looks bad, it means the protection mechanism is active. This is commonly monitored in products like galvanized steel safety ropes, where the coating must degrade before the core is compromised.

- Red Rust: This is the red or brown iron oxide everyone recognizes. It appears only after the coating has failed completely and the base metal is being eaten away. In most industrial specs, the appearance of red rust marks the definitive end of the part’s life.

The Timeline of Failure and Defining ‘Failure’ for Your Application

“Failure” is not a universal term in accelerated corrosion testing; it is defined by your specific application requirements. We help clients set the right benchmarks based on where the product will live.

- Aesthetic Failure: For decorative parts or visible consumer goods, the first sign of white rust (often within 24-48 hours) is considered a failure because it ruins the look.

- Functional Failure: For hidden structural components or rugged hardware, we often ignore white rust. The test continues until red rust appears (often 96 to 400+ hours), signaling that structural integrity is at risk.

By clearly defining these thresholds, we ensure that a test report translates into actionable data rather than just a pass/fail grade.

Beyond Salt Spray: When to Use Cyclic Corrosion Testing (CCT)

Simulating Humidity and Drying Cycles for Better Correlation

While the standard Neutral Salt Spray (NSS) test is the industry workhorse for quick quality control, it lacks the nuance of reality. Nature doesn’t keep metal constantly wet; it rains, the sun comes out, and the moisture evaporates. To bridge the gap between the lab and the field, we often recommend Cyclic Corrosion Testing (CCT) for a more accurate service life prediction.

Unlike the static “always wet” environment of ASTM B117, CCT introduces a realistic rhythm of wet, dry, and humid phases. This is crucial because corrosion mechanisms change as electrolytes concentrate during drying. For critical hardware like serrated safety washers used in fluctuating outdoor climates, relying solely on static moisture tests can be risky. The expansion of corrosion products during the dry cycle can crack coatings that would otherwise survive a standard salt fog test.

Why CCT Offers Superior Environmental Exposure Correlation:

- Realistic Stress: It mimics the natural atmospheric oxidation simulation, including UV exposure and temperature shifts.

- Complex Geometries: It is far better at detecting failure points in complex assemblies, such as swaged soft loop slings, where salt traps in crevices and dries out.

- Material Specificity: It accurately tests modern high-performance coatings that are engineered to resist cyclic fatigue rather than just static soaking.

If your product is destined for the automotive or offshore sectors, moving beyond basic salt spray to cyclic testing provides the data needed to guarantee durability in the real world.

FAQ: Common Questions About Salt Spray Testing Duration

Does 96 Hours Salt Spray Mean 5 Years Outdoors?

At XLUIG, this is the most frequent question we encounter during service life prediction. While there is no universal conversion factor due to the complexity of global environments, the industry uses a general “Rule of Thumb” to bridge the gap between lab data and reality.

Here is the rough correlation we use for 24H Salt Spray Test vs. Real-World Years estimations:

| Salt Spray Duration (NSS) | Estimated Service Life (Standard) | Estimated Service Life (Coastal) |

| 24 Hours | 1 Year | 120 Days |

| 96 Hours | 4 Years | 480 Days |

| 192 Hours | 8 Years | 960 Days |

Note: These figures are benchmarks for quality control, not guarantees. A standard ASTM B117 or ISO 9227 neutral salt spray test subjects parts to constant wetness, whereas real-world conditions include drying cycles and UV radiation.

Why doesn’t the test match real life exactly?

Real-world corrosion involves complex atmospheric oxidation and varying humidity. A salt fog chamber creates a worst-case scenario to accelerate failure. For example, when we test Dacromet coated spring washers, they might withstand 480+ hours in the lab, but their actual longevity depends on whether they are installed in a dry warehouse or a marine dock.

What counts as a “failure” in the test?

It depends on the spec. For some, failure is the first sign of white rust (zinc corrosion); for others, it is the appearance of red rust (base metal corrosion). We help clients define these pass/fail criteria to ensure their surface finishing quality control aligns with customer expectations.